An activity centre for babies and toddlers, an Indian restaurant, an indoor golf centre – and a mini experimental steel plant. These businesses are among those that make up a small retail and industrial estate in the city of Woburn, Massachusetts.

“People are dropping off their kids. That kind of shows you an extreme example of what the future of steel looks like,” says Adam Rauwerdink, vice president of business development at US-based green steel start-up, Boston Metal. “You can be making steel and sharing a parking lot with a daycare.”

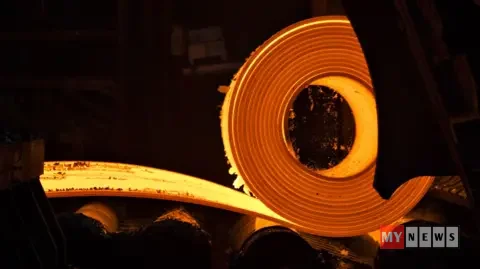

Boston Metal has come up with a way of using electricity to remove oxides and other contaminants from iron ore, which is the substance you have to mine from the Earth before you can make new steel.

The process involves distributing the ore within an electrolyte and then using electricity to heat this mixture to 1,600C. Molten iron then separates from impurities and can be tapped off.

Plus, a handful of emerging start-ups such as Boston Metal say they can go one better and use electricity for the iron-making process, a crucial step in making brand new, or virgin, steel.

For iron-making, some plants could use green hydrogen – made using electricity from 100% renewable sources – says Simon Nicholas, lead steel analyst at the Institute for Energy Economics and Financial Analysis.

But switching iron and steel-making plants over to green hydrogen hasn’t gone as smoothly as some had expected.

“We’re seeing projects cancelled, proponents pulling out of projects all over the place,” says Mr Nicholas, of green hydrogen initiatives, specifically.

These headaches would suggest that there is a niche for companies developing alternative ways of making iron and steel. Boston Metal is one.

“It looks a lot like how we make iron and steel today – it’s a lot easier to conceive how that would get to scale [as a result],” says Paul Kempler, an expert in electrochemistry and electrochemical engineering at the University of Oregon.

However, he notes that there are still challenges in ensuring that electrolysis systems like this don’t corrode too quickly over time. Boston Metal says it hopes to have its first demonstration-scale steel plant operational by 2028.

Separately, the US firm Electra is taking a different approach to producing highly purified iron from ores. Unlike Boston Metal, Electra’s process runs at a relatively low temperature, around 60-100C. First, iron ore is dissolved into an acidic solution and then an electrical charge causes the iron to collect onto metal plates. This is similar to the process currently used for making sheets of copper and zinc today.

“These plates are extracted automatically out of the solution and the iron is harvested,” says Sandeep Nijhawan, co-founder and chief executive. A demonstration plant in Colorado, which could produce 500 tonnes of iron annually, is currently set to open next year.

Initially, iron produced in this manner would cost more than iron made using traditional techniques. But that “green premium” could fall away should the company be able to scale sufficiently, says Mr Nijhawan.

Mr Nicholas says that emerging technologies such as this are hopeful, but one challenge they face is in breaking into the market in a big way within just a few years, since the need to slash emissions and curb climate change is become more and more urgent: “We’re running short of time for addressing carbon emissions.”

Companies such as Electra and Boston Metal offer a completely different vision of the steel-making industry but they won’t get far without further investment – and a market that appreciates what they are doing.

President Donald Trump’s tariffs on steel imports to the US are supposedly designed to protect the domestic steel industry – and yet they risk raising the cost of steel substantially for US customers.

I ask whether Dr Rauwerdink, for one, is happy to see this move, or not. “We’re quite happy to see the strong focus on critical metals,” he says, arguing the tariffs are “beneficial” for Boston Metal.

Though he acknowledges that US government’s attitude towards renewable electricity, which Boston Metal says it want to prioritise as an energy source, has changed lately. And, globally, keeping the cost of renewable energy low is important for any firm hoping to electrify industries previously dominated by fossil fuels.

“The industry has growing pains there, for sure,” he says.